|

The magnetic examination of the parts makes it possible to detect instantly all the external and internal defects which could compromise the safety of these parts and those which a radiographic observation or another investigation would be powerless to detect (sinkholes, internal cracks, blowholes, taps, weld defects or deterioration of the metal by mishandled grinding). This process, to which SNCM made a large contribution, thus allows the control before and after thermal treatments, and shows in an indisputable way the alterations hitherto invisible due to the internal tensions caused by quenching, as the figures show opposite. The observation of the magnetic spectrum provided by the metalloscope makes more accessible the study of forging and stamping and also allows the highlighting of steel forging lines and the heterogeneities that can result. The relatively easy use of the metalloscope allows for the rapid monitoring and control of many standard parts, which facilitates production while increasing the quality of the material produced.  Metalloscope for magnetical examination. |

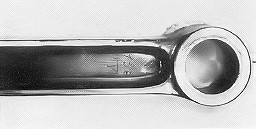

Ball raceway before examination.  Ball raceway after examination.  Magnetic examination of a connecting rod for fiber drawing study. |

| [ | Previous | | | France | | | Index | | | Next | ] |

| [ | Home | | | About | | | Contact | | | Top | ] |

Translated with Google Translate