For a specific type of engine having reached the stage of <<bench>> approval and fitted to an appropriate airplane, the purpose of flight tests is:

This flight performance endurance test is therefore the dedication of the adaptation work in the same way that the bench test is that of the development of the engine performed at the manufacturer. Adapting the engine to the aircraft is also the logical outcome of this development, in particular operating conditions, installation and atmosphere practically unachievable bench test.

Adaptation research must be conducted in such a way as to find on the airplane all the operating characteristics of the engine at the test bench as power, temperatures and consumptions which have been satisfactory and this by reducing the easements as much as possible. to impose on the cell: weight, safety, resistance to advancement.

The questions to be studied for the adaptation of the engine to the airplane will therefore be mainly:

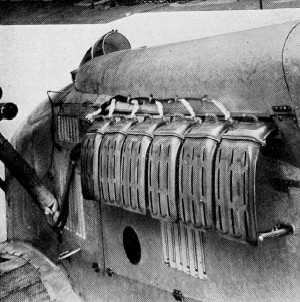

Cooling will be regulated to allow flights under the harshest operating circumstances of the aircraft, and with varying atmospheric conditions. It will therefore be necessary to ensure the correct operation of the various cooling circuits to perform numerous temperature measurements at different points of these circuits: motor and radiator oil inlet and outlet, engine and radiator coolant inlet for liquid-cooled engines, cylinder and cylinder temperatures, inlet and air temperatures, outlet hoods for air-cooled motors using thermoelectric torques, steam or resistance thermometers, fuses, etc. In addition, the <<cost>> of this cooling from the point of view of forward resistance will be determined by static and dynamic pressure measurements at various appropriately selected points (air inlet and outlet of the radiators for liquid-cooled engines , air intake and exhaust hoods and baffles for air-cooled engines). These measurements will make it possible to evaluate the air velocities in radiator cowlings and shrouds, the pressure drops and the absorbed powers and consequently to determine the improvements to be made to these various elements as shapes, dimensions or locations.

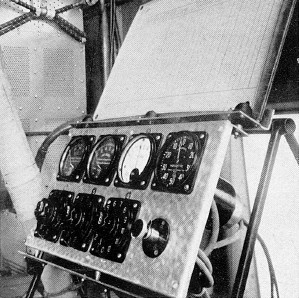

Control chart of temperatures and pressures. |

The difficulty of carrying out these measurements simultaneously and precisely because of the speed with which it is necessary to proceed, leads the S.N.C.M. to study a new apparatus that will record automatically and simultaneously by photography all the temperature and pressure measurements characterizing the operation of an engine at a determined instant. This equipment is expected to provide the greatest service and save valuable time during testing.

As regards the adaptation of the propeller and the verification of the power supplied by the engine in flight, the S.N.C.M. is in the process of developing a <<Torque Meter>> that will accurately assess this power during the flight, a more accurate method than currently in use and that is to refer to the Bench Engine Power Curves test according to the rotational speeds.

For aircraft vibration studies the apparatus used for the factory tests, and already described in this manual, may be used with the same accuracy in flight.

Finally, from the point of view of research on carburetion, apart from the pressure measurements necessary to verify the proper supply of the engine with carburetted air (pressure measurements in the ventilators, in the carburetor and the compressor) and measurements of air temperatures before and after carburetion (icing) and which can be carried out with the aircraft already mentioned, S.N.C.M. has a remarkably precise means of investigation with the method of analysis of exhaust gas developed by Mr. Bonnier, and which was discussed in the previous chapter.

Temperature measurement and gas sampling on aircraft engine. |

| [ | Previous | | | France | | | Index | | | Next | ] |

| [ | Home | | | About | | | Contact | | | Top | ] |

Translated with Google Translate